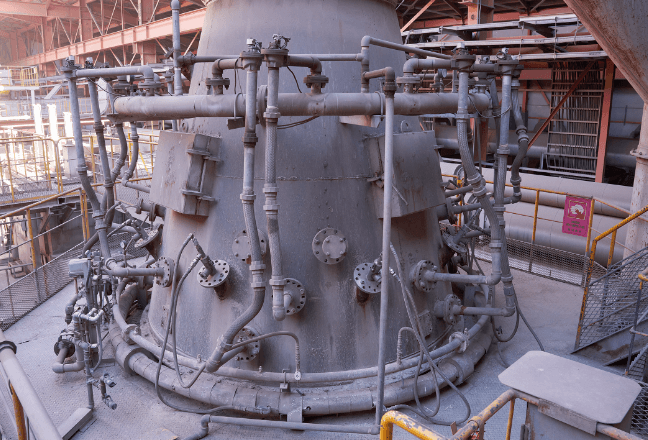

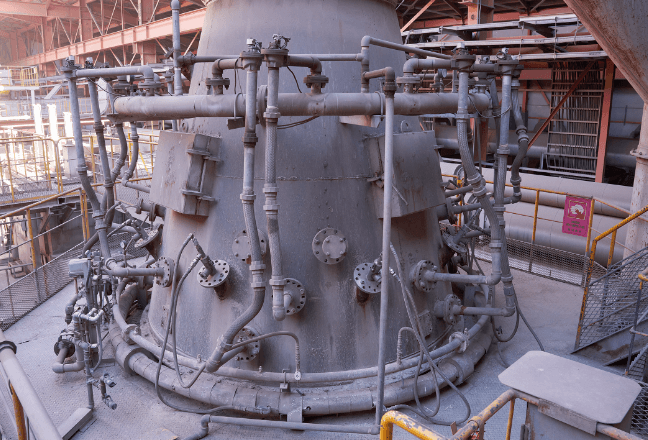

Rotary kiln

Valuable metal sorting equipment

Ash pit

Desuperheater

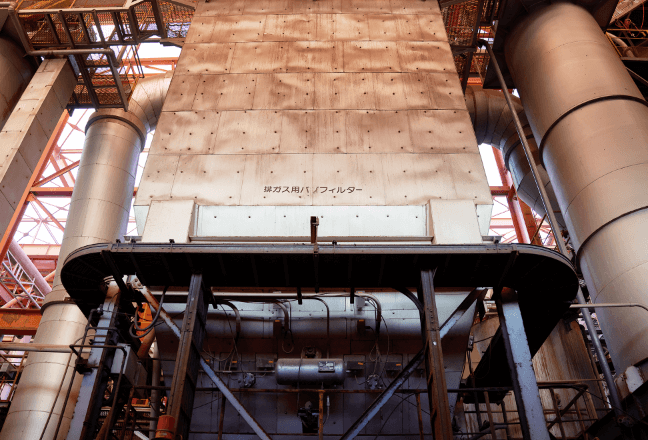

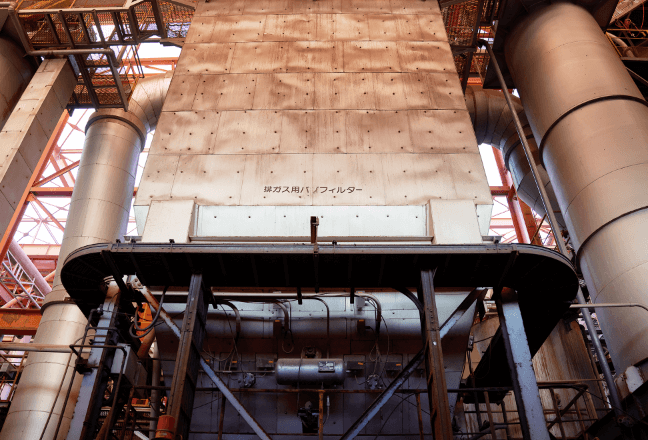

Bag filter

Crushed product silo

Product stockyard

Central control room

Ash pit

Desuperheater

Bag filter

Crushed product silo

Product stockyard

Central control room

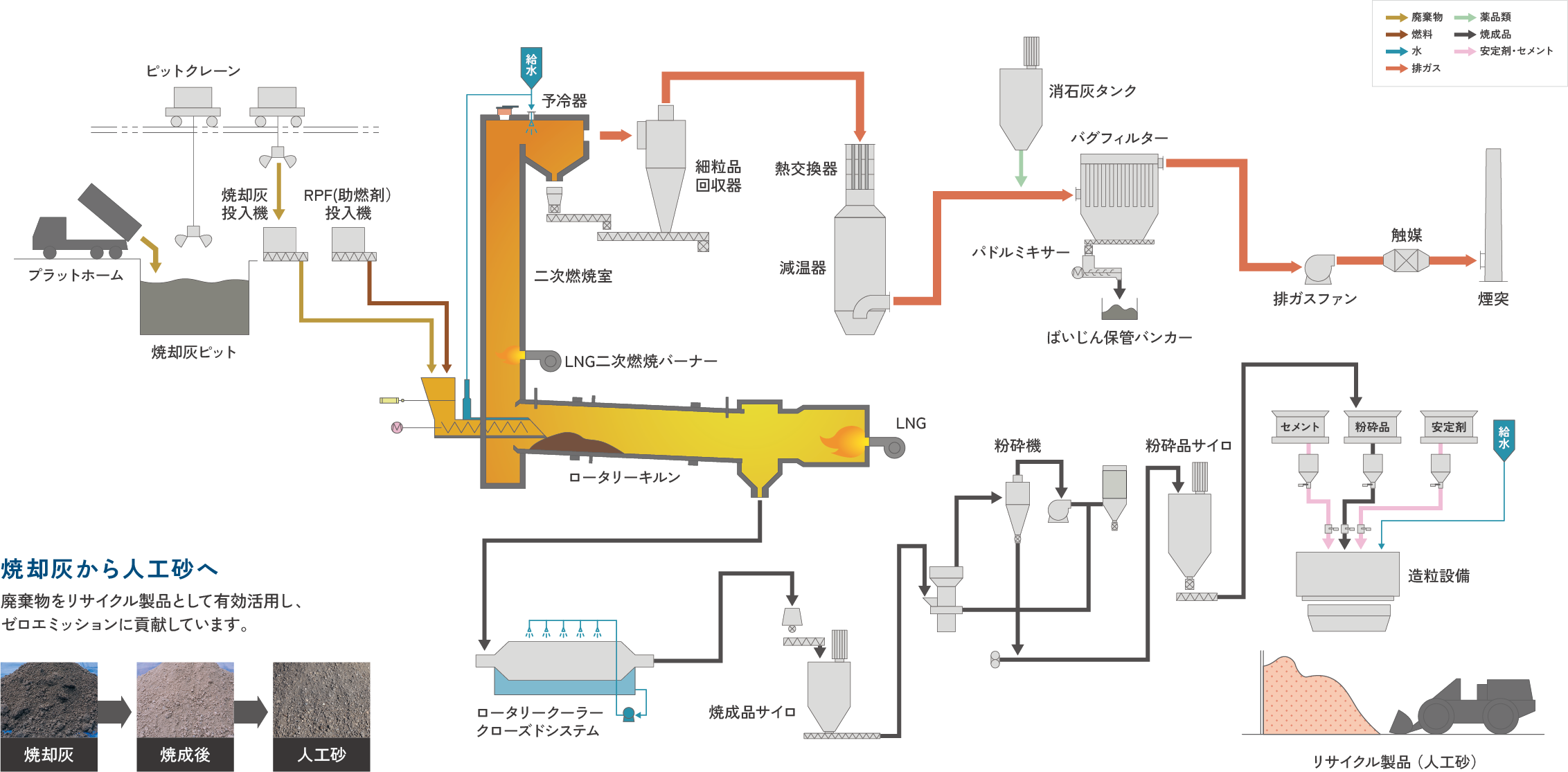

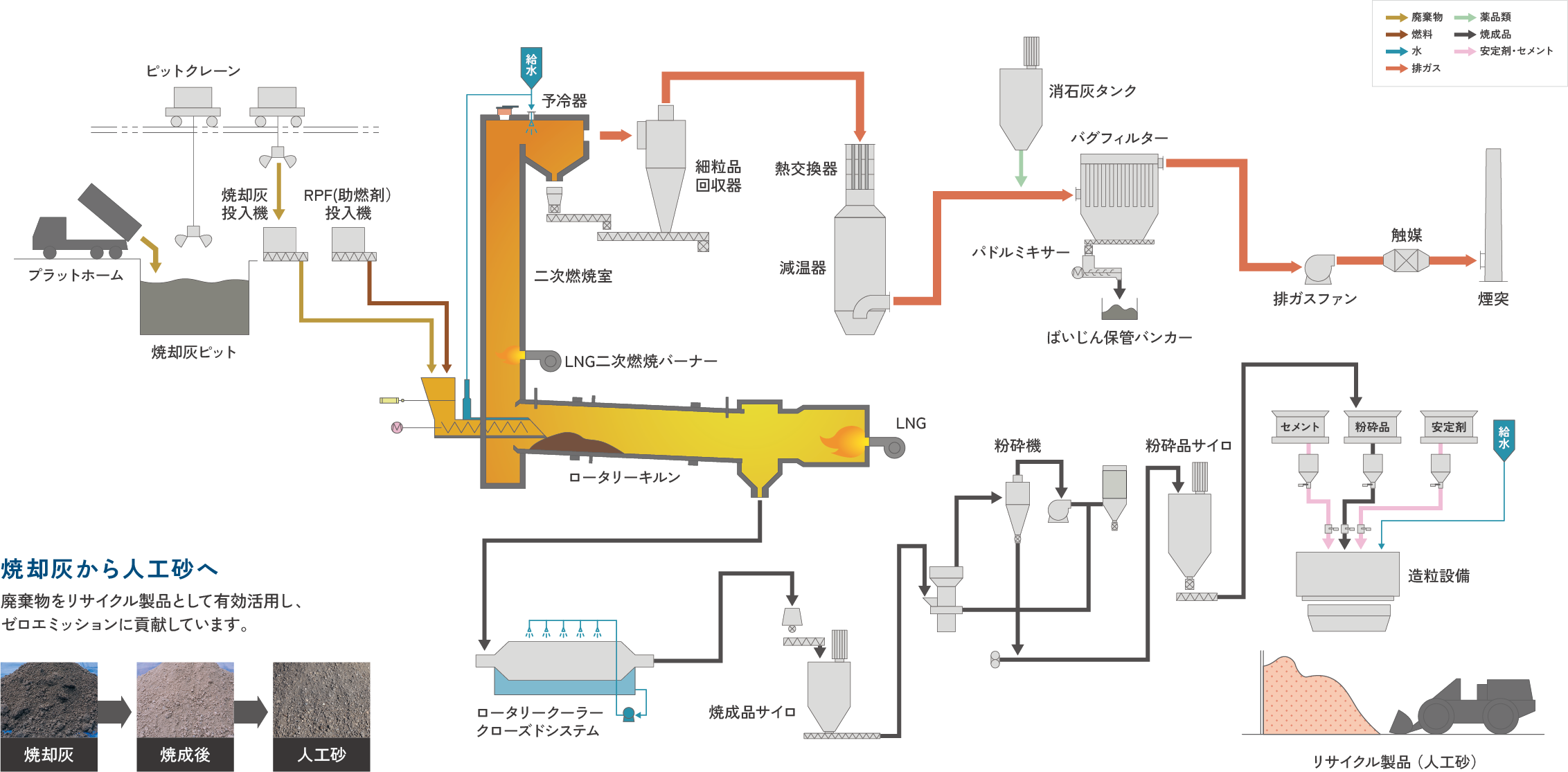

Processing flow

zoom in

| Waste to be processed |

|

|---|---|

|

■General waste 【Burning】 Incinerated ash, soot and dust ■Industrial waste 【Burning】 Cinders, sludge (limited to inorganic substances), slag, soot and dust |

|

| Outline of processing facilities |

|

|

|

| Outline of preprocessing facilities |

|

|

|

| Outline of receiving facilities |

|

| |

| Location | |