We contribute to carbon neutrality

by

generating our own electricity for

our

necessity.

We generate electricity by recovering the

thermal energy

generated during the waste

incineration process as steam. We

secure the

necessary power for use at the plant and sell

any

surplus to the power company. This

reduces energy

consumption and contributes

to the reduction of CO₂

emissions.

|

|

|

|

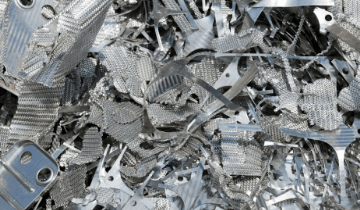

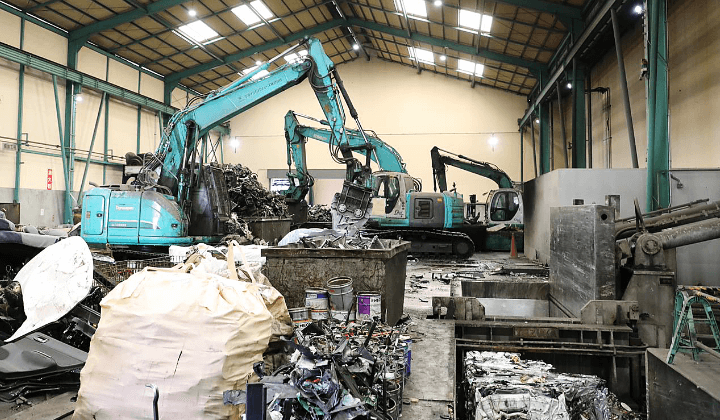

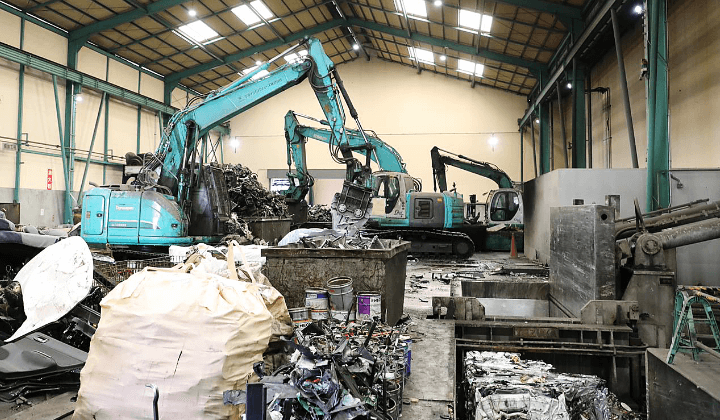

Car recycling

Used automotive parts sales

(Domestic)

Used automotive parts sales

(Overseas)

Recycling

|

|

Used automotive parts sales (Domestic) |

|

|

Used automotive parts sales (Overseas) |

|

| Recycling |

閉じる

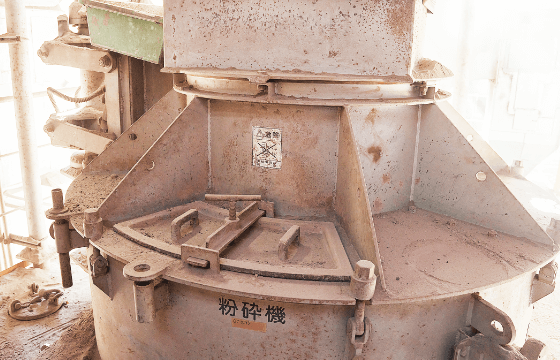

人工砂(アークサンド)の

リサイクルプロセス

閉じる