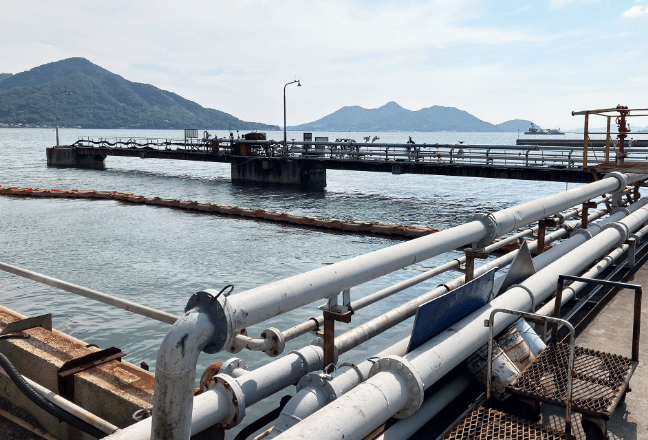

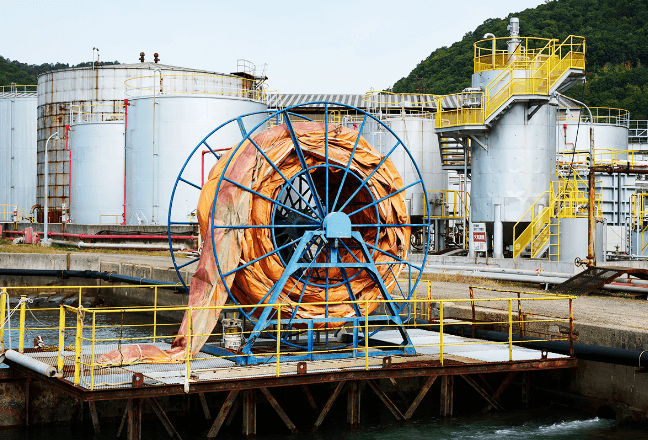

Dolphin pier

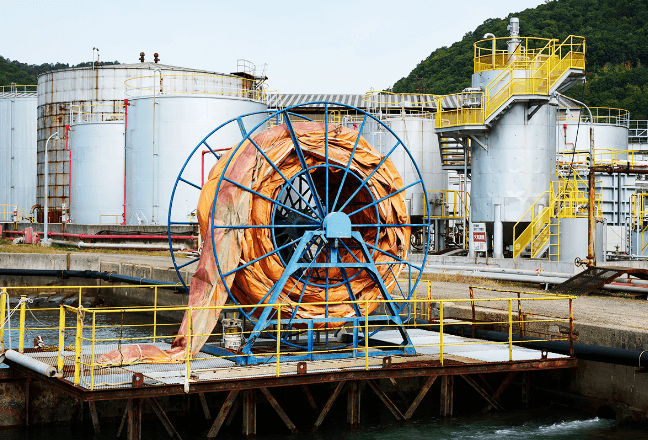

Tank

Oil fence

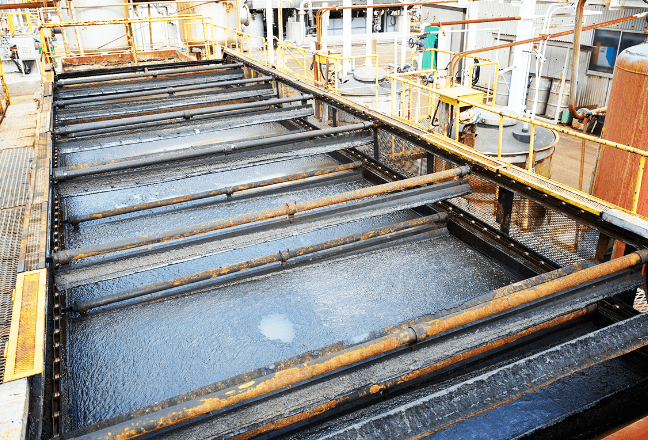

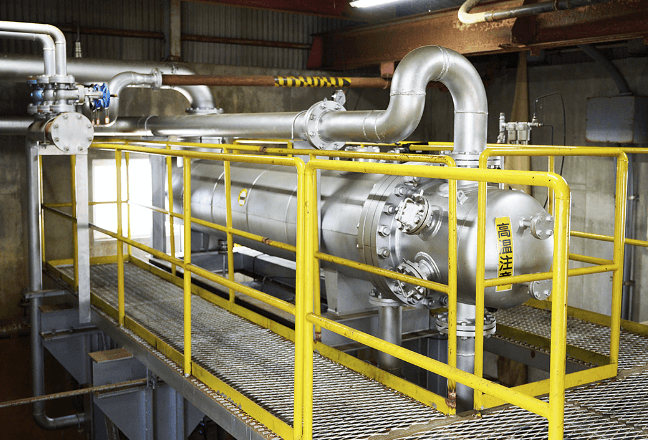

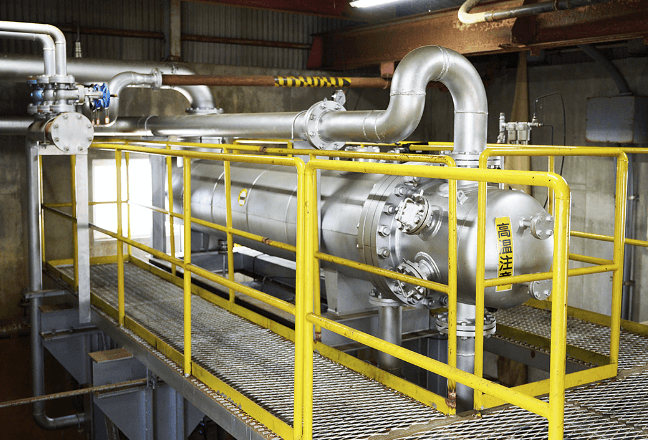

Pressurized floatation separation tank

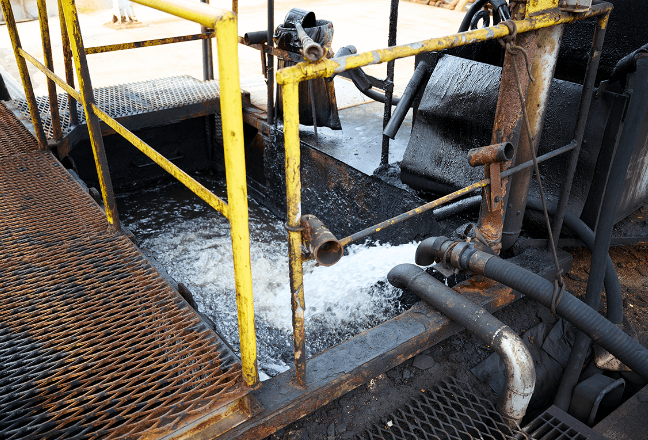

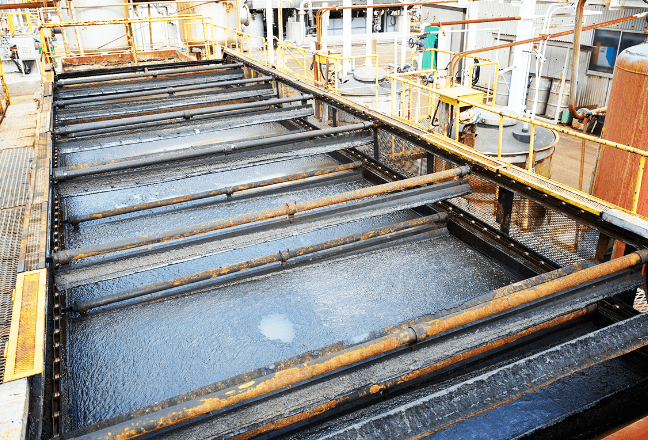

TPI oil and water separator

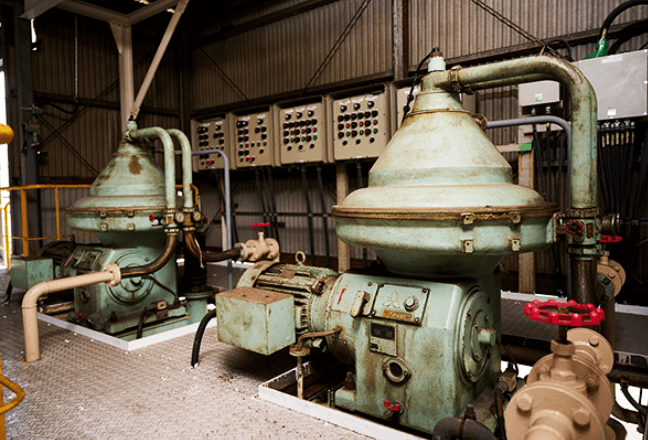

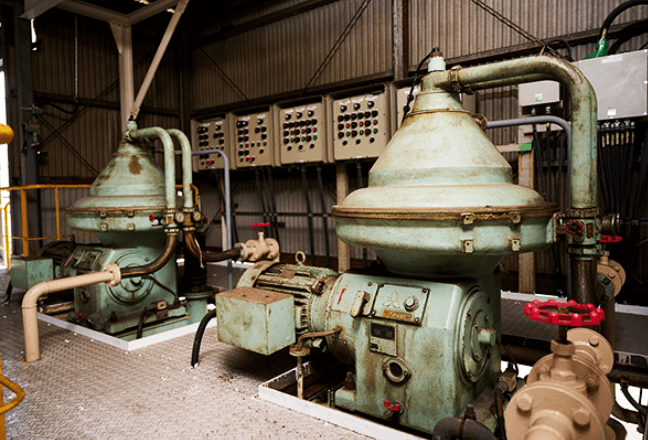

Centrifuge

Boiler

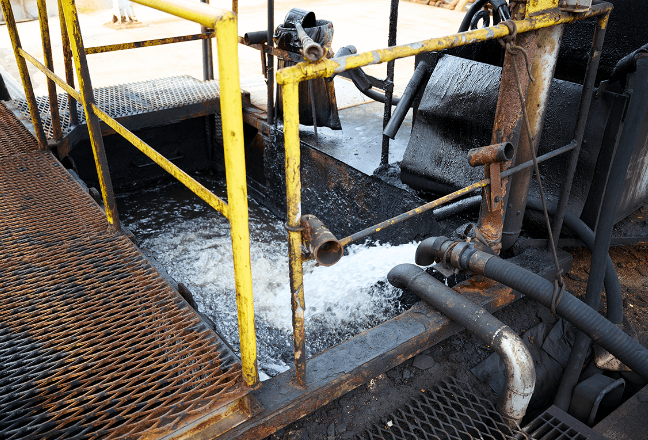

Butterworth pump

Oil fence

Pressurized floatation separation tank

TPI oil and water separator

Centrifuge

Boiler

Butterworth pump

| Waste to be processed |

|

|---|---|

|

■Ship waste oil slops, tank washing water, bilge, ballast, sludge, chemical washing water ■Industrial waste/waste oil ■Specially controlled industrial waste/flammable waste oil |

|

| Outline of processing facilities |

|

| Pier docking facility |

|

| 5,000DWT | |

| Location | |