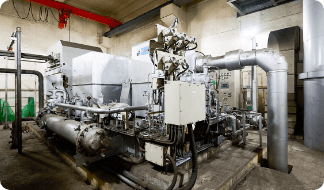

We are working on implementing thermal

recycling,

which generates electricity from

the heat energy

generated during waste

incineration. In addition to

securing the

necessary electricity by generating 4,950

kW

in-house, we sell surplus electricity to reduce

CO₂

emissions.

We reuse as much of the collected waste as

possible

and manufacture and sell recycled

products. By

effectively utilizing these

products as materials, fuel, or

fertilizers, we

are able to contribute to the establishment

of

sustainable consumption patterns.

We promote the use of sustainable, non-

fossil energy

sources and have installed

many solar panels at our

group companies’

facilities. One such power generation

facility

is located in Kurashiki City’s Mizushima

district.

This facility has contributed to

reducing crude oil

consumption by 450

kiloliters per year and 1,000 tons

worth of

CO₂ emissions.

*Using emission factors based on the 2021 Law

Concerning Global

Warming Countermeasures

announced by electric power companies

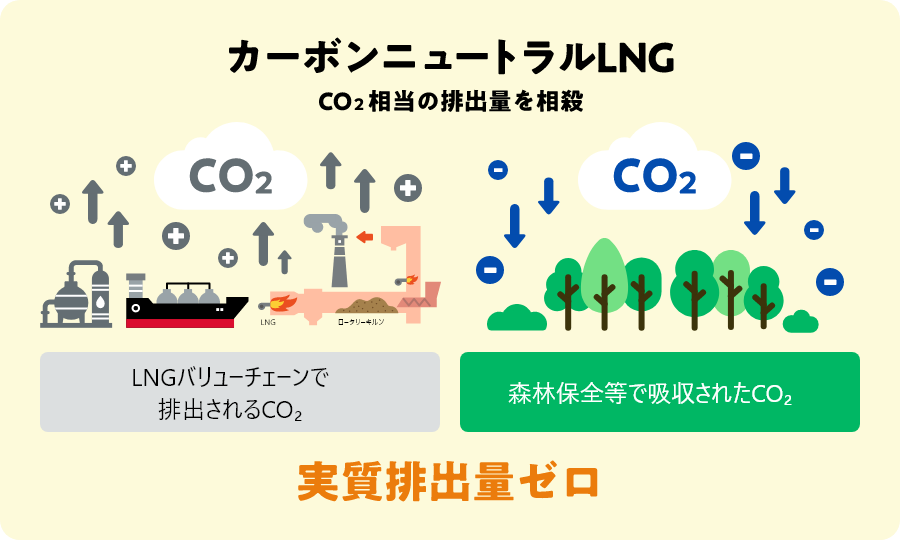

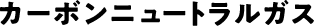

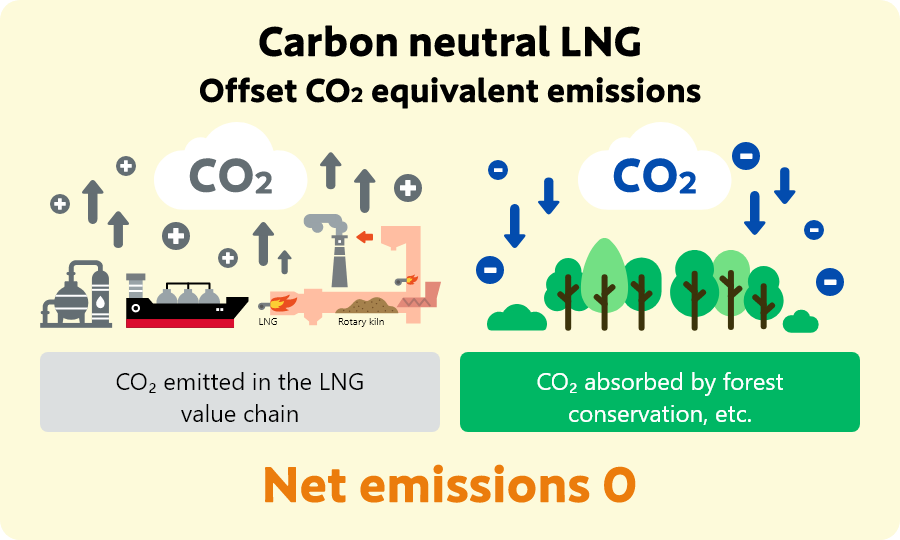

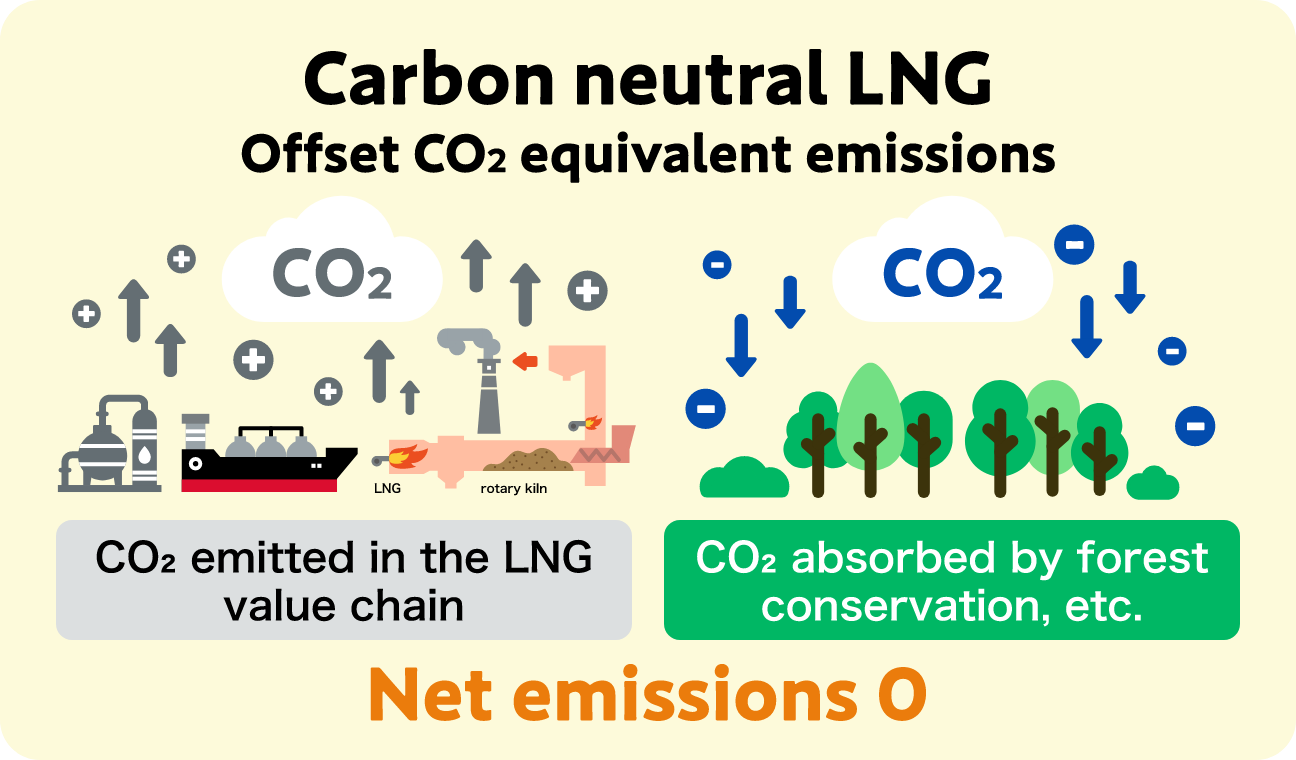

The Saitama Plant uses “carbon neutral gas”

for all its

natural gas use and strives to

reduce its environmental

impact while

building a recycling-oriented society.

The Saitama Plant uses “carbon neutral gas”

for all its

natural gas use and strives to

reduce its environmental

impact while

building a recycling-oriented society.

Carbon neutral gas

It is a type of gas that employs carbon credits

certified by

reputable certification organizations for

CO₂ emission

reductions in forest conservation

projects around the world.

The carbon credits offset

greenhouse gases generated in all

processes from

natural gas extraction to combustion.

Freight transportation conducted by trucks

and other

means is encouraged to embrace

less environmentally

harmful methods.

TSUNEISHI KAMTECS group of

companies

aims to reduce transportation CO₂ emissions

by promoting industry-wide business

partnerships and

streamlining freight

logistics.

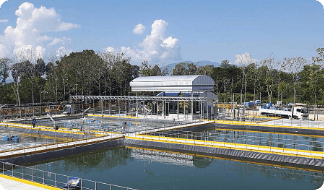

In 2013, we established a local subsidiary in

Thailand.

The subsidiary works on designing,

constructing, and

maintaining wastewater

treatment plants. The plants

make efficient

use of limited water resources by

returning

treated water to rivers or reusing it as water

for

cleaning the plant.